Introduction:

A recent report from the Central Drugs Standard Control Organisation (CDSCO) has exposed alarming issues with the quality of cough syrups manufactured in India. This revelation is a matter of great concern, as over 50 companies, out of 2,104 tested, have failed to meet the standard quality requirements. Let’s delve into the details of this report, examining the reasons behind the failures and the steps being taken to address this critical issue.

Quality Test Failures:

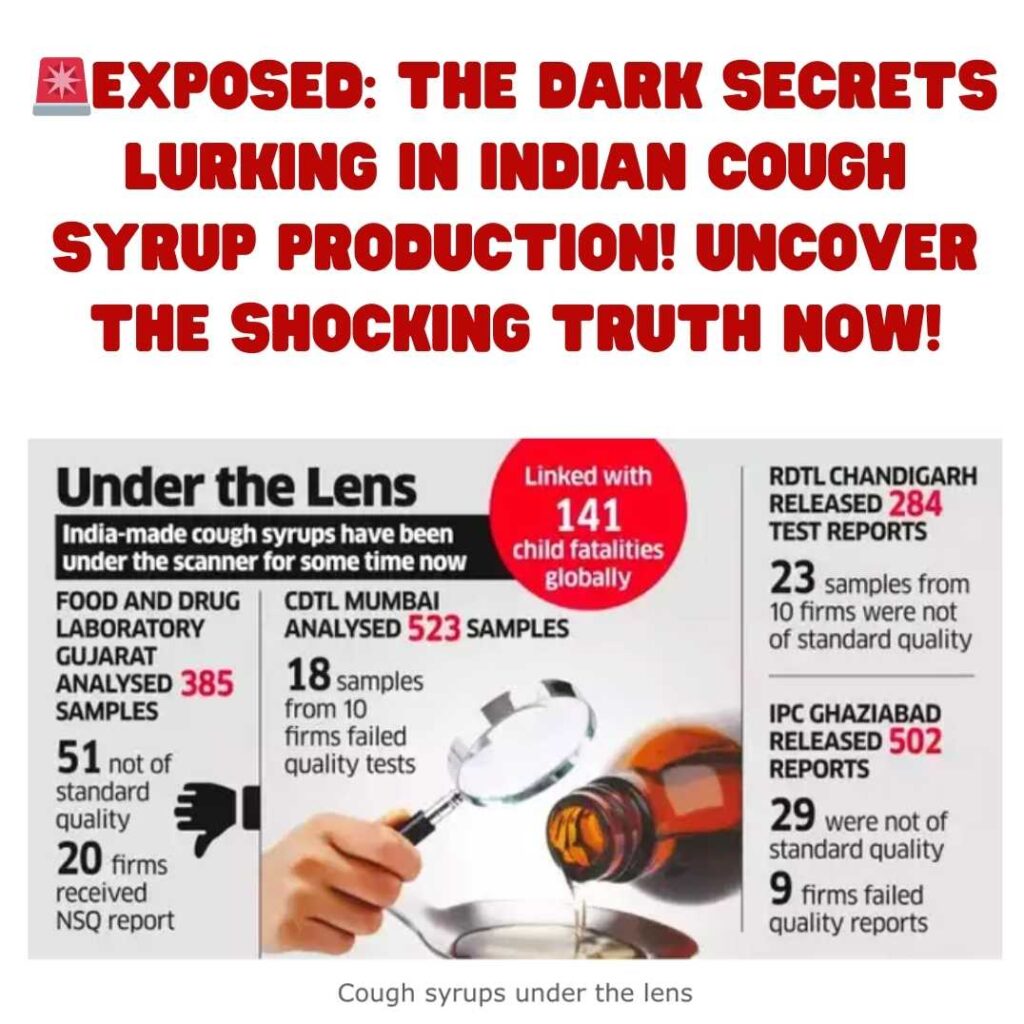

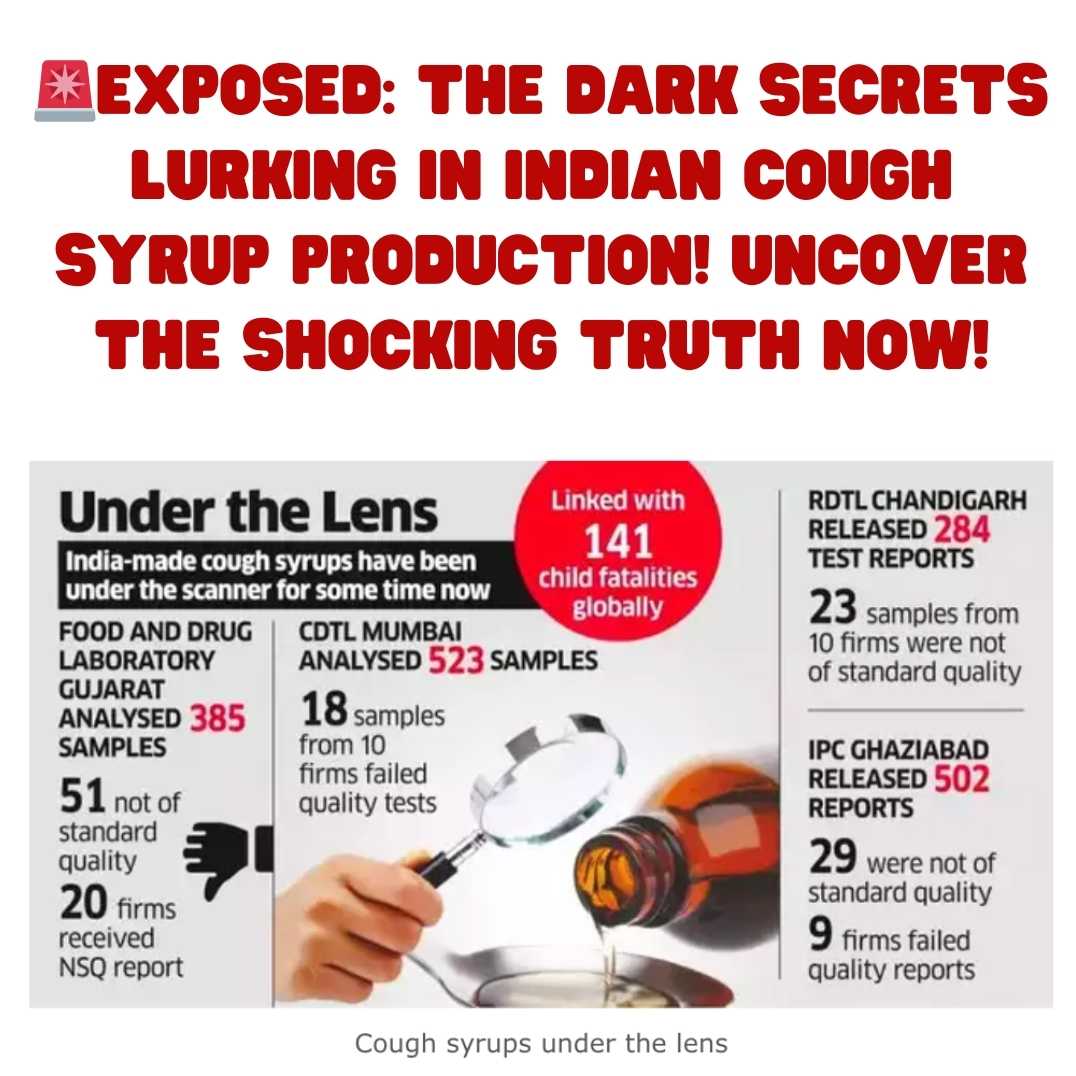

The CDSCO report reveals that 6% of cough syrup samples from 54 pharmaceutical companies did not pass the mandatory quality test for export. Out of the 2,014 samples tested in various government laboratories across states like Maharashtra, Gujarat, Uttar Pradesh, and Chandigarh, 128 samples (6%) were found to be “not of standard quality” (NSQ).

Testing Laboratories and Their Findings:

Government laboratories responsible for testing these samples include well-known institutions such as the Indian Pharmacopoeia Commission in Ghaziabad, Central Drugs Laboratory in Kolkata, Central Drug Testing Laboratory in Chennai and Mumbai, Central Drug Testing Laboratory in Hyderabad, Regional Drugs Testing Laboratory in Chandigarh and Guwahati, and any NABL-accredited state drugs testing laboratory.

In Gujarat, 51 out of 385 samples tested were found to be NSQ, indicating a significant issue in the quality of cough syrups. Similarly, in the Ghaziabad laboratory, 29 out of 502 samples failed to meet the required quality standards. This widespread occurrence of substandard quality cough syrups across different regions raises serious questions about the overall safety and reliability of these products.

Government’s Response:

In response to these concerning findings, the Union commerce ministry issued a crucial directive in May. This directive makes it mandatory for all cough syrup manufacturers to subject their stocks to testing at government laboratories before exporting. The goal is clear: to prevent the export of potentially harmful products and protect consumers both within India and around the world.

Previous Incidents:

The government’s intervention is not without reason. Previous incidents have highlighted the potential dangers associated with India-made cough syrups. In December of the previous year, Marion Biotech’s cough syrup was linked to the tragic deaths of 18 children in Uzbekistan. Furthermore, on October 5, 2022, the World Health Organization (WHO) issued a medical product alert regarding four cough syrups – Promethazine Oral Solution, Kofexmalin Baby Cough Syrup, Makoff Baby Cough Syrup, and Magrip N Cold Syrup. These products, manufactured and exported by Haryana-based Maiden Pharmaceuticals, were linked to the deaths of 66 children in The Gambia.

Conclusion:

The government’s report brings to light a critical issue that demands urgent attention. With over 50 cough syrup manufacturers failing quality tests, the safety and reliability of these products are now under intense scrutiny. The proactive measures taken by the government, such as mandatory testing before export, indicate a commitment to addressing these concerns and ensuring the well-being of consumers.

Moving forward, it is crucial for manufacturers to prioritize and uphold stringent quality standards, both domestically and globally. By adhering to these standards, pharmaceutical companies can contribute to the overall improvement of public health and safety. As the government takes steps to rectify the situation, it is essential for all stakeholders to work together to restore trust in Indian-made cough syrups and ensure that such lapses in quality are swiftly addressed.

What do you think?

It is nice to know your opinion. Leave a comment.